According to the U.S. Environmental Protection Agency, the construction industry was responsible for more than 600 million tons of debris in 2018. For reference, that is more than twice the amount of municipal solid waste the country produced that year from homes and businesses. The volume of waste resulting from demolitions, renovations, and road repairs is expected to increase to 2.2 billion tons by 2025.

According to the U.S. Environmental Protection Agency, the construction industry was responsible for more than 600 million tons of debris in 2018. For reference, that is more than twice the amount of municipal solid waste the country produced that year from homes and businesses. The volume of waste resulting from demolitions, renovations, and road repairs is expected to increase to 2.2 billion tons by 2025.

While some projects blindly dump the debris in the nearest landfill, others prefer to take a more sustainable approach. In a previous blog, Emerald defined Net Zero Waste and the business imperative. In this blog, we look at how the Circular Economy and Net Zero Waste are complimentary topics.

The impetus for this blog comes from Recycle Track Systems (RTS), who partners with haulers to incorporate routing technology that streamlines waste collection. RTS is a certified B-Corporation and is recognized for their positive impact on the environment.

The Circular Economy

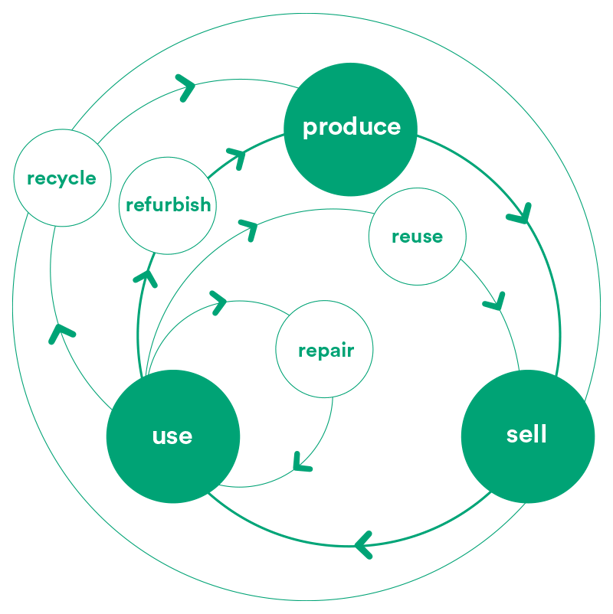

According to the World Economic Forum, a circular economy is “an industrial system that is restorative or regenerative by intention and design.”

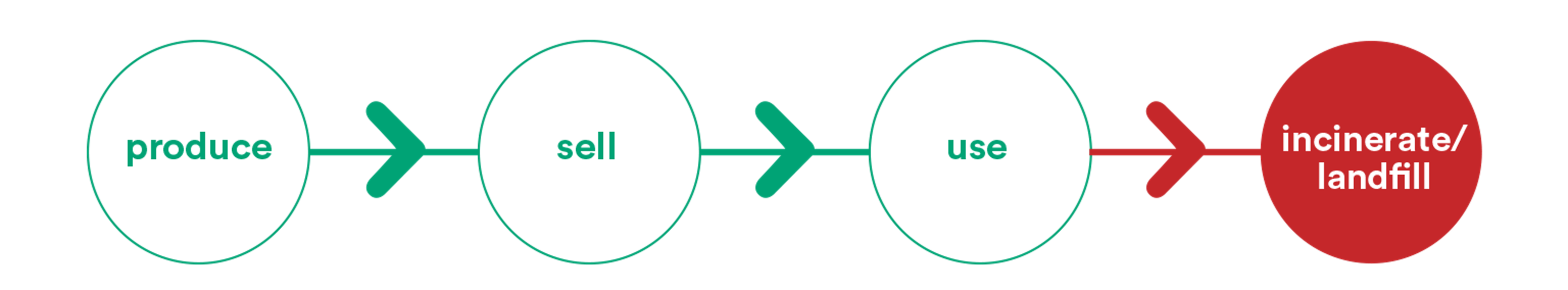

To better understand circular economy, we can compare it to our current industrial economy, which is dominated by linear processes. Imagine a massive network of conveyor belts where goods are produced, used and ultimately discarded. This one-way flow has a clear beginning and end.

Our current industrial economy is dominated by linear processes.

Linear Economy

A circular economy works quite differently. It closes the loop on the linear “take-make-consume-throw away” pattern by retaining the highest utility and value of products, components, and materials for as long as possible. With circular economic activity, waste is reduced to a minimum because everything produced is transferred and used somewhere else, continuously.

Circular Economy

How Can Construction Waste Management Bring About a Circular Economy?

Currently, our system of linear economy prioritizes the use of raw materials in production--or rather, construction. That means that crews are using new timber, bricks, and cement every time they break ground. Likewise, by the time a project is complete, if not carefully managed, any generated waste is taken straight to the nearest landfill or incinerated.

Conversely, the basic premise and goal of a circular economy is the overall reduction of waste and, therefore, pollution. It requires us to imagine a world where we only use as many natural resources as necessary. For instance, it calls upon projects to prioritize construction materials like steel and concrete to contain high amounts of recycled content. Or it compels a project to reuse its own demolition waste as fill for the next building.

In addition to reusing or recycling items, another route is to repair or refurbish them. That allows materials to live on in other builds and prevents companies from taking too many raw materials from nature. Alternatively, if raw materials are needed, it's ideal to prioritize renewable sources rather than draining natural resources that will take a long time to recover--an example is the recent trend to use mass timber that is sustainably forested.

Other strategies, such as building life extension, are less obvious examples of how construction sites can participate in a circular economy. As they say, an existing building is the most sustainable building. Namely, if buildings are built to last, building materials won't be needed as often. Then, the construction industry can focus on predictive maintenance of existing structures.

How Can the Construction Industry Get to Net Zero Waste?

Dealing with waste on a construction project requires a two-fold approach. First, begin by planning for waste management early in design, especially if demolition is part of the scope. Set goals and build accountability into contract agreements.

In addition to only ordering the exact quantity of materials a project would need, try to ensure they include sustainable content or were sustainably harvested and manufactured.

Even if you calculate the exact amount of materials needed to complete a project down to the last bathroom tile, there's bound to be some excess waste. That’s where establishing a diversion plan for each waste stream is important. In many instances, construction waste could be valuable to a number of outlets. When it is separated on site or at an off-site facility, each waste stream increases in value.

Net Zero Waste can be achieved! After all, some of the methods we’ve mentioned are also a good way to stay on budget. And if nothing else, practicing sustainable material sourcing and waste management will bring us closer to the promise of a circular economy and our 2030 climate goals!

Posts by Tag

- Sustainability (173)

- sustainability consulting (146)

- Energy Efficiency (129)

- Utilities (94)

- LEED (88)

- Sustainable Design (69)

- green building certification (60)

- energy audit (48)

- ESG (46)

- construction (43)

- GHG Emissions (37)

- WELL (32)

- carbon neutrality (32)

- tax incentives (28)

- costs (27)

- net zero (27)

- energy modeling (20)

- electric vehicles (17)

- Energy Star (14)

- Housing (14)

- Inflation Reduction Act (13)

- water efficiency (13)

- Social Equity (12)

- decarbonization (12)

- diversity (10)

- NGBS (7)

- fitwel (7)

- Earth Day (6)

- Engineering (6)

- electrification (5)

- mass timber (5)

- non-profit (5)

- retro-commissioning (5)

- Emerald Gives (4)

- News Releases (4)

- B Corp (3)

- COVID-19 Certification (3)

- Customers (3)

- EcoVadis (3)

- Indoor Air Quality (3)

- PACE (3)

- Arc (2)

- DEI (2)

- EcoDistricts (2)

- Green Globes (2)

- cannabis (2)

- CDP (1)

- SITES (1)

- furniture (1)

- opportunity zone (1)

- womenleaders (1)