In the Northern Hemisphere, the autumn season brings a time to enjoy the crisp leaves, cooler weather, and holiday festivities - including Oktoberfest! While fall is still a lovely season for some, the climate is changing, and extreme weather events and disasters are already afoot. Five, ten, fifteen years in the future, the climate will be more extreme and unpredictable, directly affecting the production, quality, and cost of the Oktoberfest staple: beer. Brewers across the nation are focused on steps they can take today to protect against climate change tomorrow. Let’s dive in and learn more!

How Are Climate and Beer Related?

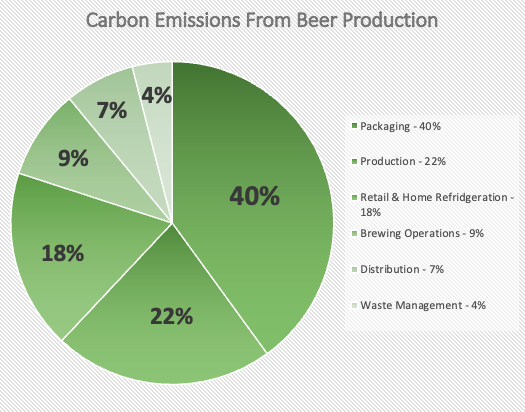

Simply put, the environmental impact of the brewing industry is extremely resource-intensive. To begin, the two most tangible concepts for brewing are water use and carbon emissions. It takes approximately 19.5 gallons of water to produce the malted barley for a single 8-ounce glass of beer. In addition to water use, the production of crops, brewing of beer, processing, packaging, distribution, and refrigeration of beer have a massive environmental footprint. When it comes to carbon emissions, the leading segment is packaging at 40%, followed by production at 22% according to the farm-to-landfill lifecycle of beer.

Climate-Impacted Agriculture and Water Systems

Beer begins with the barley, hops, and other crops that go into the brew. Currently, most breweries source ingredients from mass-production industrial agriculture farms. These farms cut and regrow crops each year and depend on large quantities of water and chemicals. The more sustainable option is to source from small farms that practice regenerative agriculture to conserve water.

While American farms are currently able to sustain supply based upon the resource-intensive methods of hop and barley farming, as climate change events - such as droughts - intensify in length and frequency, water will become scarcer. A recent study in Yakima Valley, WA found that 300-400 gallons of water are needed to grow a single pound of hops. (And though every beer recipe is different since some require more hops than others, to give you some perspective, IPAs typically need about three pounds per keg while a pale ale will only have about half a pound of hops.)

Because of the large quantity of water required for such a small amount of hops, when demand increases, water will become a large expense, increasing the price of hops, barley, and beer as a result. Furthermore, as the water table lowers, the hardness of the water will increase and negatively affect the quality of the crops. And that’s not all! The negative impacts continue to trickle down from there – with low-quality hops and barley, they will be harder to grow, and then the demand will rise as well. In the end, climate change will push not only the plants’ limits but also the brewers’ and consumers’ wallets.

Conserving and Diverting Water in Breweries

There is hope. Breweries can work towards more sustainable practices through simpler, tangible, more affordable methods that do not require new technology. One such way is through reducing water consumption by metering water taps in facilities. In Cleveland, OH, Market Garden Brewery wanted to pinpoint its sustainability efforts by conserving more water. By installing meters on their water taps and observing their baseline levels, they were able to decide where they could take action to reduce water consumption and began implementing practices to conserve water, saving money on their energy bill.

Seismic Brewing in Santa Rosa, CA has developed a process to recapture wastewater from the brewing process to use for cleaning and other needs in the facility. By creating a filtering system that holds, separates, and uses physical, UV and chemical filters, they are able to divert their wastewater into a closed-loop system. Working towards the goal of being a net-zero water building is an attainable goal for breweries that want to become more climate-friendly!

Alternate Solutions for Climate-Friendly Beer

Transportation, production, refrigeration, packaging, and distribution of beer make up the majority of the carbon emissions of beer production. Some companies have targeted these areas by reducing their carbon footprint through big technological changes. New Belgium, a large Colorado-based craft brewery, attained a carbon-neutral certification for its Fat Tire beer by switching to renewable energy and offsetting some of its carbon emissions by planting trees. BrewVo, another Colorado-based brewery, created a revolutionary process that separated the water from the alcohol to ship concentrates to distributors, allowing them to reduce water usage, extend product life, reduce shipping costs, increase supply chain efficiency, and reduce carbon emissions by cutting out the excess water from their product.

Updating Systems to Shrink Carbon Footprints

In already-existing buildings, an easy way to reduce long-term carbon emissions to reach long-term goals of net-zero carbon is by updating older systems. With the guidance of Emerald’s expert consultants, MadTree’s new Alcove Bar and Restaurant recently opened in one of Cincinnati, Ohio’s historic buildings. Their building was updated to include new HVAC systems that are high-efficiency heat pumps, and the energy flow throughout the building was streamlined, reducing energy use and redirecting carbon emissions offsite. Alcove's sustainability performance supports MadTree's multi-dimensional approach to addressing its impact.

Moving toward brewing a more sustainable future can be as simple as taking measures to reduce your water usage and making energy-saving swaps to heating, cooling, and refrigerant systems. Do you want to upgrade your brewery to shrink your carbon footprint, and increase your energy efficiency while working towards a more sustainable future? Reach out to Emerald to see how we can brew a great plan for you!

Posts by Tag

- Sustainability (173)

- sustainability consulting (146)

- Energy Efficiency (129)

- Utilities (93)

- LEED (88)

- Sustainable Design (69)

- green building certification (60)

- energy audit (48)

- ESG (46)

- construction (43)

- GHG Emissions (37)

- WELL (32)

- carbon neutrality (32)

- tax incentives (28)

- net zero (27)

- costs (26)

- energy modeling (19)

- electric vehicles (17)

- Energy Star (14)

- Housing (14)

- Inflation Reduction Act (13)

- water efficiency (13)

- Social Equity (12)

- decarbonization (12)

- diversity (10)

- NGBS (7)

- fitwel (7)

- Earth Day (6)

- Engineering (5)

- electrification (5)

- mass timber (5)

- non-profit (5)

- retro-commissioning (5)

- Emerald Gives (4)

- News Releases (4)

- B Corp (3)

- COVID-19 Certification (3)

- Customers (3)

- EcoVadis (3)

- Indoor Air Quality (3)

- PACE (3)

- Arc (2)

- DEI (2)

- EcoDistricts (2)

- Green Globes (2)

- cannabis (2)

- CDP (1)

- SITES (1)

- furniture (1)

- opportunity zone (1)

- womenleaders (1)